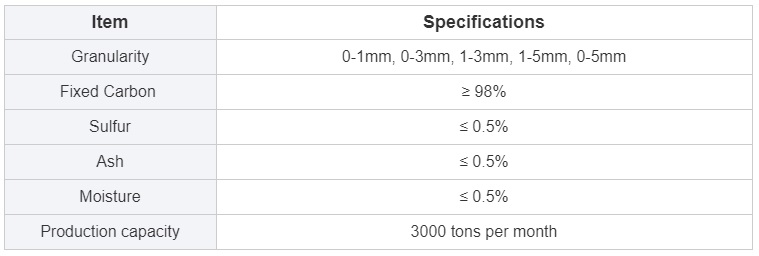

High carbon content low sulfur calcined petroleum coke is made of calcined petroleum coke as raw material, then going through fully graphitization of the continuous graphitization process under the high temperature of minimum 2600íŠ . Afterwards, through crushing, screening and classification, we supply our users with the different particle size between 0-50mm at the customers' request.

Acting as the inoculant and carburizer, it's widely used in the special steel smelting and precision casting process, especially meeting the requirement of high quality product and strict control of sulfur content in the ductile iron and grey iron casting industry. lt's also used as reducer agent in the nuclear reactor, the absorbent of heavy metal in the waste water treatment system and the raw material of graphite cathode in the aluminum electrolysis cell.

Note:

1. S of the coke: S is one of harmful impurity of the iron smelting. If the S content above 0.07%, the iron will be waste product.

2. P of the coke: The P content should be bellow 0.02-0.03%, when you iron smelting.

3. Ash of the coke: The ash add 1%, the coke need add 2-2.5%.

4. Volatile matter of the coke: According to the content of the volatile matter we could adjust the grade of the maturity of the coke.

5. Moisture of the coke: Moisture will make the M40 on the high side and make the M10 on the low side.

Pls contact us for free to get more details.

Welcome to inquiry

Whatsapp/wechat: +8615833690562

Email: bella@hbkangnaixing.com